CAMOPLAST / CAMSO TRACK MAINTENANCE

WARNING

Do not insert hands or feet into or near the System unless the engine is off, and the vehicle is stopped with the security brake engaged.

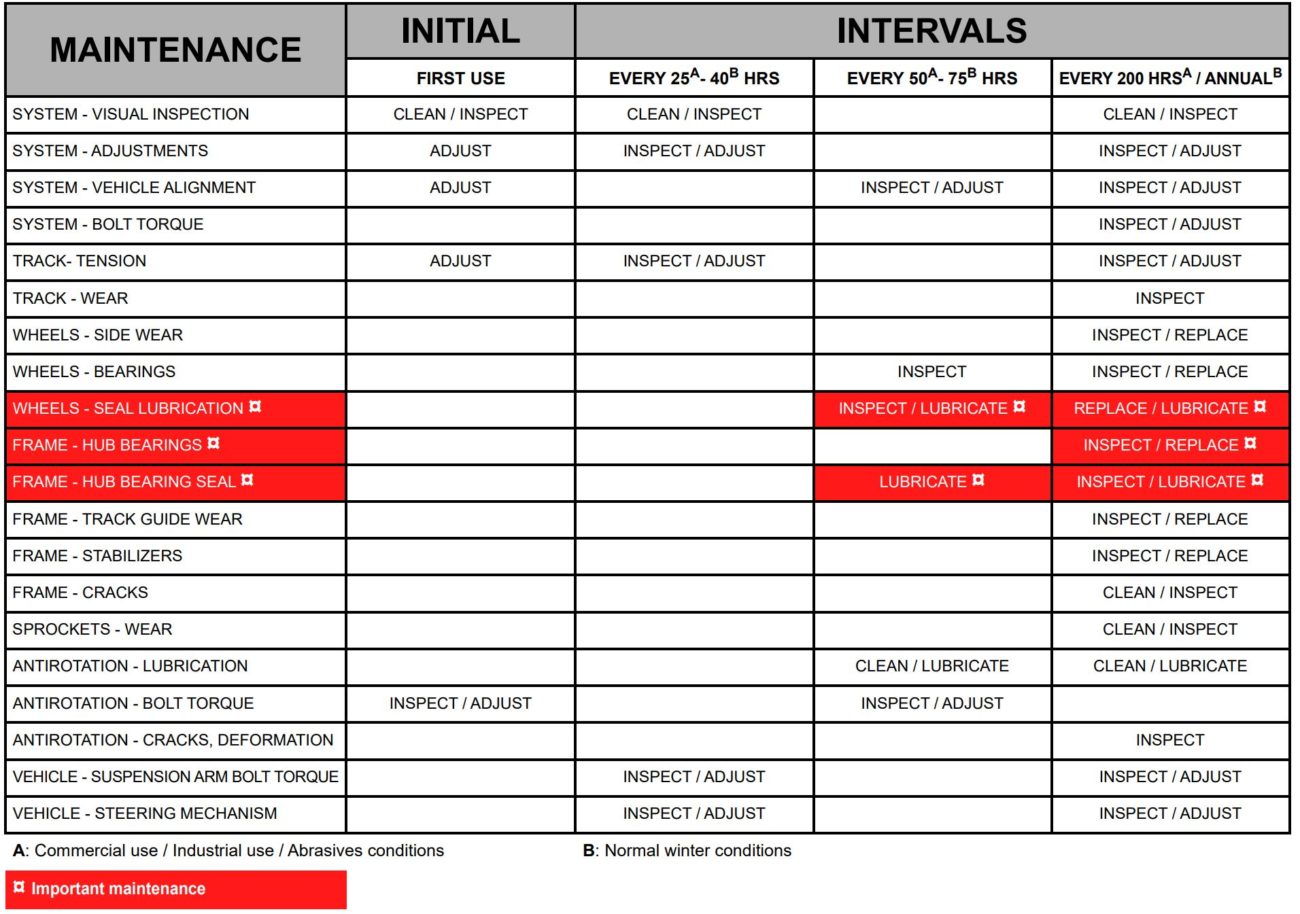

CAUTION: Regular inspection, adjustment and lubrication of the Track System is essential to its good running order and safe operation. Users are responsible to perform maintenance and regularly adjust their Track System. The “Maintenance” section provides the necessary information to perform adequate maintenance on the Track System.

CAUTION: Failure to do regular maintenance at the prescribed intervals and perform the preventive adjustments indicated in the maintenance schedule can result in premature wear and important breakage on the Track System that will not be covered under the warranty. Users are responsible to follow the maintenance schedule provided by the manufacturer

CAUTION: Camso recommends not using a brake cleaning solvent to clean the Track System. This may damage sealing components and stickers. The maintenance schedule has been established in order to provide optimum durability for your Track System. The type of usage and the conditions in which the Track System is used, have a direct bearing on the frequency of maintenance actions to perform. After inspection of your Track System, you will be able to determine if the recommended maintenance intervals are correct or to adjust them as needed. For optimum performance and maximum

durability, please refer to the maintenance chart below

MAINTENANCE - TASKS

• Inspect: Component(s) must be examined with care. If an anomaly is noticed, the malfunctioning component(s) must be repaired or replaced.

• Clean: Component(s) must be cleaned of any dirt, dust or contaminant liable to impair the proper operation of the Track System.

• Adjust: Component(s) must be adjusted or readjusted according to the manufacturer’s adjustment recommendations. Refer to the relevant section of the User Manual.

• Lubricate: Component(s) need to be lubricated according to the manufacturer’s recommendations. Refer to the relevant section of the User Manual.

• Replace: Component(s) must be replaced to avoid serious breakage.

MAINTENANCE - SPECIFICATIONS

System

• Visual Inspection: Visually inspect each Track System to detect any defect or anomaly that can impair proper functioning of the systems.

• Adjustment: Perform or verify angle of attack adjustments on the systems according to the manufacturer’s recommendations. Refer to the Adjustments section on page 10.

• Vehicle Alignment: Perform or verify the vehicle alignment with the Track Systems installed. Follow the manufacturer’s

recommendations. Refer to the Alignment section on page 13.

• Bolt Torque: Check the torque of critical bolts identified in the exploded views of the system. Refer to the central pages of the User Manual.

CAUTION: Comply with the tightening torque recommendations and use a thread locker product if you come across a bolt that is not tightened to the manufacturer’s recommendations.

TRACK

• Tension: Perform or check track tension on the systems according to the manufacturer’s recommendations. Refer to “Rubber Track Tension” in the Adjustments section on page 16.

• Wear: Check wear and overall condition of the tracks on the Systems. Refer to “Wear” in the Maintenance section on page 25.

CAUTION: A damaged track can result in premature wear of Track System components.

WHEELS

• Side Wear: Check side wear on Track System wheels. Replace wheel(s) if wear is too great. Refer to “Wear” in the Maintenance section on page 25.

• Bearings: Check wheel bearings for restriction, noise or abnormal play in rotation. Replace wheel if bearing shows one of these defects.

• Wheel Seal Lubrication: Wheel seals must be cleaned of any dirt or contaminant and lubricated according to the manufacturer’s recommendations. Refer to “Lubrication” in the Maintenance section on page 21. If a seal shows damage or any defect, it must be replaced.

NOTE: Installing new seals when doing wheel maintenance is recommended.

NOTE: Lubrication done at the recommended intervals allows the wheel seals to maintain optimal sealing action and prolongs the useful life span of the wheels.

FRAME

• Hub Bearings: Check hub bearings for restriction, noise or abnormal play in rotation. Bearings must absolutely be replaced if they present a defect.

CAUTION: If a hub bearing shows a defect, replace the both hub bearings and replace hub bearings on all 4 Track Systems at the same time.

MAINTENANCE

• Hub Bearing seal: The maintenance chart recommends cleaning and lubricating the hub seal. Refer to “Lubrication” in the Maintenance section on page 22.

NOTE: Lubrication done at the recommended intervals allows the hub seal to maintain optimal sealing action and prolongs the life span of the hub bearings.

• Track Guide wear: Check wear on Track guides. Replace guides if wear is too great. Refer to “Wear” in the Maintenance section on page 26.

• Stabilizers: Verify condition of rubber cones on the stabilizer assembly of front systems and wheel axle assembly of rear systems. If the cone bores show oval-shaped wear, they must be replaced. Refer to the “Wear” section in the User Manual on page 26.

• Cracks: Visually inspect frames for presence of cracks or defects that can impair proper operation of the Track System. Replace components if damaged.

SPROCKETS

• Wear: Check wear of sprockets on the Systems. Replace if wear is too great. Refer to “Wear” in the Maintenance section on page 26.

ANTI ROTATION

• Lubrication: The maintenance chart recommends cleaning and lubricating the antirotation arms. Refer to “Lubrication” in the Maintenance section on page 23.

• Bolt Torque: Verify torque of assembly bolts on anchor brackets and anti-rotation arms at

the recommended intervals specified by the

maintenance chart.

• Cracked or bent parts: Visually inspect antirotation arms for presence of cracked or bent parts that can impair proper functioning. Replace components if damaged.

Rubber Dampers: Verify condition of rubber dampers on anti–rotation arms. Replace dampers if they are deformed, cracked or show severe wear. Refer to “Wear” in the Maintenance section on page 24.

CAUTION: When pressure washing the Track System, care must be taken to keep the water stream away from wheel and hub bearing seals and from rubber caps.

CAUTION: Hub bearings should be checked and replaced in accordance with the maintenance chart. Bearings that present abnormal play, make noise or restrict rotation of hub are indications that they must be replaced.

CAUTION: Use a breaker bar to remove the hub assembly bolt. Do not use an air impact wrench. It might cause the bolt to break.

CAUTION: Always replace washer and hub assembly bolt when removing the hub from the frame. Use new fasteners at reassembly.

SPECIAL TOOLING

Wheel Extractor

NOTE: The Wheel extractor shown below in Figure 32

can be purchased by clicking here