How to Inspect and Maintain Hub Bearings on a Track System

Ever notice vibrations or abnormal play in your track system, impacting stability while riding? It could be a sign that the hub bearings need maintenance. The hub is the heart of the track system, so it’s worth keeping an eye on it. A hub that’s in good shape will translate into a long-lasting track system with great performance.

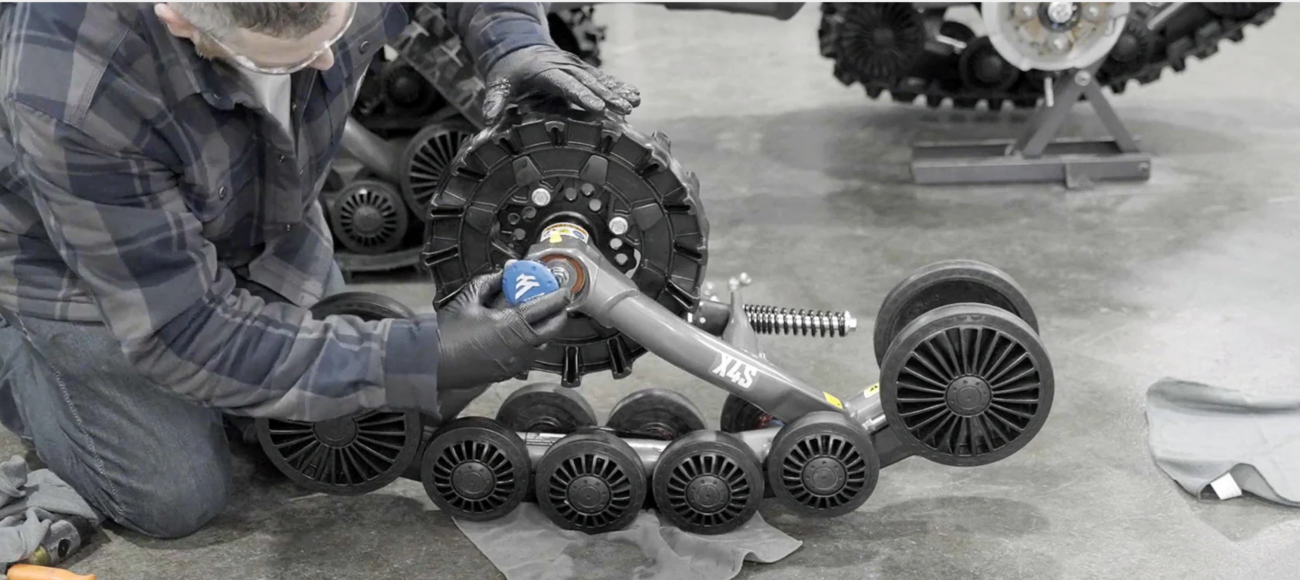

Figure it’s time to give your hub bearings a little attention? Check out this short video. It walks you through the main steps of how to inspect and maintain the hub bearings on Camso track systems. And since hub bearings occasionally need replacing, it also shows you how to do this, too. All you need is a few tools and some free time.

Maintenance steps covered in the video

Chances are you already know that it's good practice to visually inspect your vehicle and track system after every ride. But just in case you don’t, this video will certainly remind you. Specifically, what signs of damage to look for, like rust, wear, or defects.

To properly inspect the hub bearings, you’ll first need to remove the track and the system from the vehicle to expose the components at the core of the hub.

Then you’ll learn how to maintain and replace track system hub bearings that are still in good condition, and the tools you’ll need.

PRO TIPSome hub components, like the hub seal and hub bolt, can’t be reinstalled once removed.

Always have new hub seals and bolts on hand when doing any hub maintenance.

The video also helps you figure out if your hub bearings are beyond saving. If that’s the case, you can get replacement hub bearings.

If you notice your hub bearings are making unusual noise, restricting rotation of the hub, or presenting abnormal play, don’t ignore it. Grab a buddy, grab your tools, and level up your DIY skills with the help of this video.